COLLAPSIBLE PROTOTYPING CASE

work Contact

The Collapsible Prototyping Case is a dual-function carrier designed for DIS students to securely transport both pin-up boards and prototyping materials across campus. With portfolio and backpack modes, this foldable case transforms to meet different needs while minimizing bulk and preserving studio aesthetics. Inspired by our struggles hauling Bristol boards in rain and snow, we prioritized lightweight structure, collapsibility, and weather resistance. Adjustable straps, magnetic closures, and modular handles ensure both comfort and intuitive use. Built from cardstock, foam, and EVA in early iterations, the final prototype proved the design's functionality. Next steps would focus on using more durable materials and implementing user-adjustable modes, such as satchel-carrying.

01 — Problem Framing & observation:

We were tasked with designing a product specifically for our peers in the DIS program, and through observation, we noticed students struggling to carry large pin-ups and prototypes. We spoke to classmates and identified a need to easily transport polished papers and prototyping materials from various places.

“I’ll have to go the the studio again to pick up my stuff…It’s just so out of the way.”

- Student 02

“I just put my pin-up in a tote bag and pray it doesn’t bend or get wet”

- Student 03

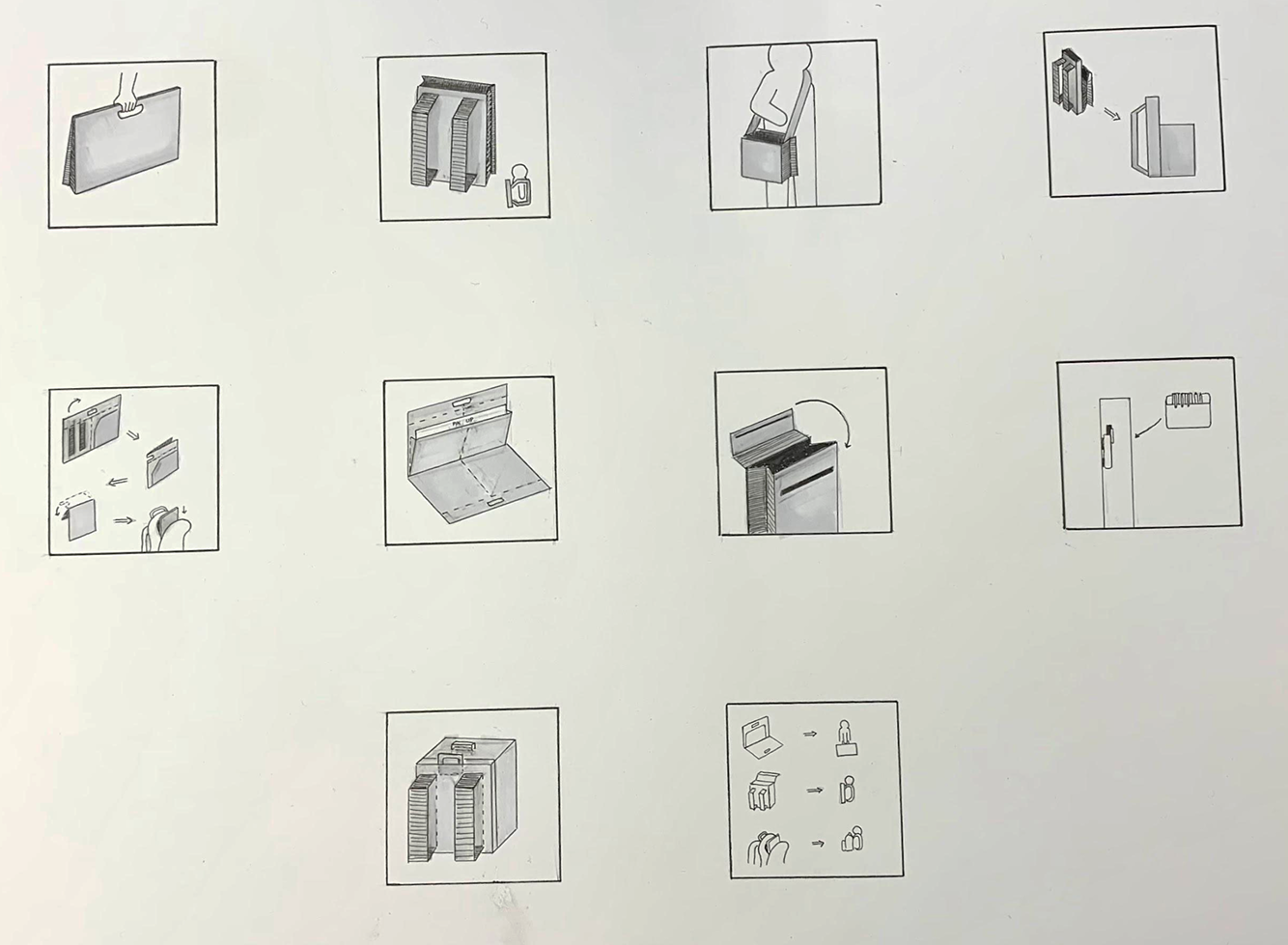

02 — Brainstorming & Sketching

We sketched a range of design thumbnails based on traits like collapsibility, waterproofing, and lightweight storage, leading to a multi-mode case with folding features, snap closures, and adaptable handles. After presenting our concept, user feedback highlighted the need for comfortable straps, a sturdier base, and ergonomic handle placement for the best user experience.

Sketches and thumbnails of various carrying modes, which eventually led to our final pin-up sketch (image 3).

03 — Ideation & Prototyping

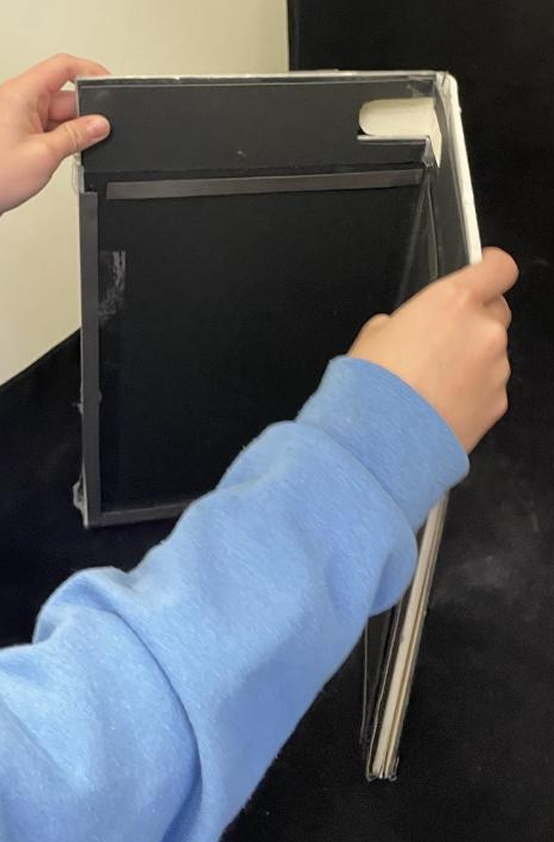

We built a scaled-down cardstock model to test folds, closures, and transitions between portfolio and backpack modes.

The detailed process on how we made our first model can be found in the full report.

Final Rough Prototype

Our cardstock prototype helped tremendously as a reference for our final prototype and assured us that our design met all functions regarding our problem statement.

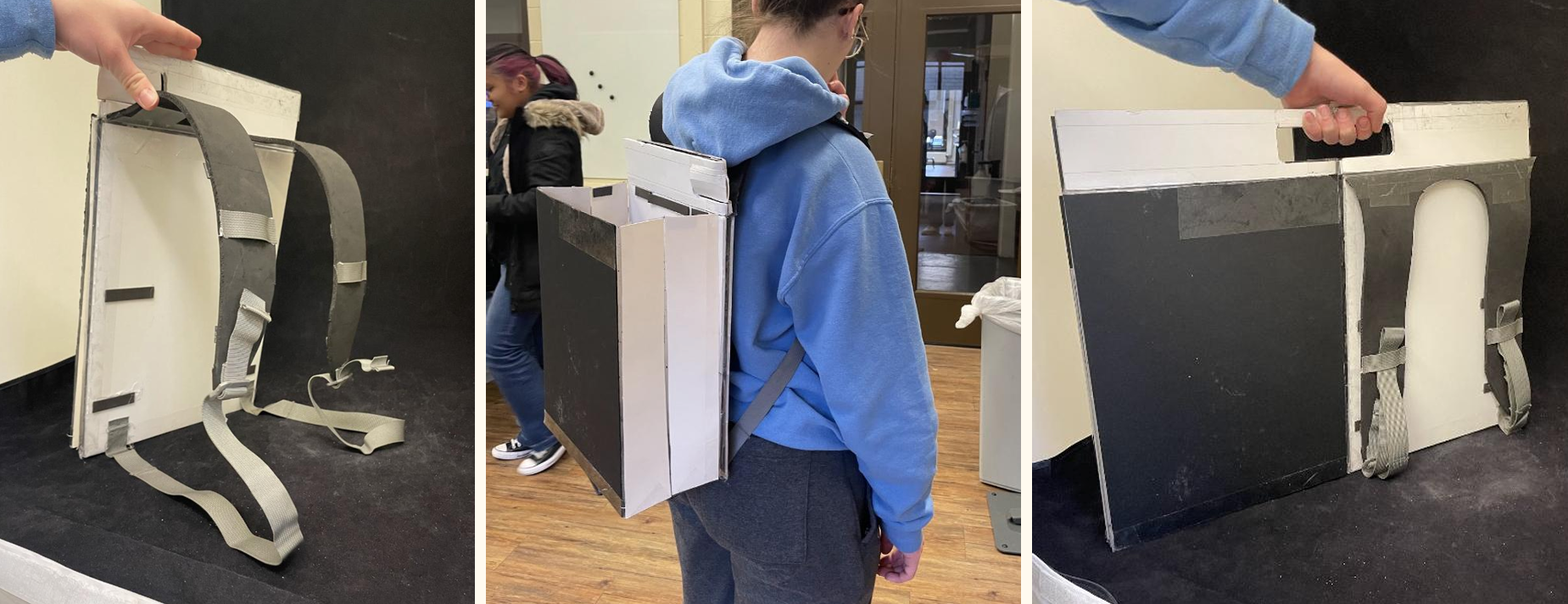

04 — Final Prototype Construction

Our full-scale model used foam board, EVA sheets, magnets, and packing tape to replicate final functionality, revealing insights into form, comfort, and material layering (details of insights can be found in the full report).

Our final product was constructed similarly to our initial paper prototype and was effectively the same idea on a higher fidelity scale. Insights into the construction and materials can be found in the full report.

05 — User Testing

In-class and external testing showed that users preferred the pin-up mode over the backpack, liked the magnet closures, and requested alternate carrying options like satchel straps when commuting calls for a hands-free option.

Insights from our in-class and external user tests can be found in the full report.

06 — next steps

Future iterations will explore briefcase and satchel modes, laser-cut polypropylene for fold precision and lightness, embedded magnets and other snap features, and more inclusive strap designs for varied body types.

New sketch with briefcase inspired handle.